3D surface inspections in automotive manufacturing

2013-01-31

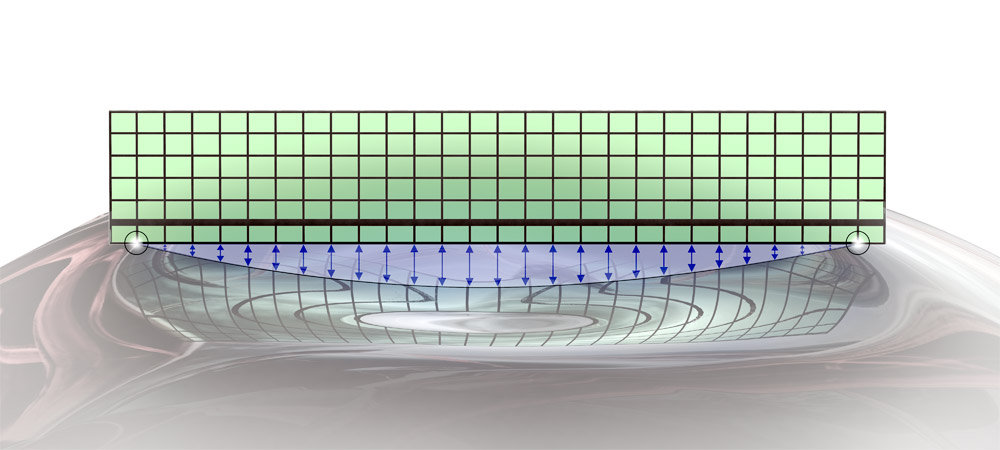

For surface inspections in automotive manufacturing, INB Visions AG (a company in the Micro-Epsilon group) has developed a “digital whetstone”. This process is now used for the first time with plastic fuel filler doors. Unlike inspection processes in a press shop and in sheet-based car body manufacturing, the components are now stripped digitally, not physically. The surface is stripped optically and will not be damaged in the process. Once the 3D sensor has detected the fuel filler door, a virtual line is defined (which corresponds to the length of a physical whetstone). This line is guided point-by-point along the component in a predefined direction, and it rests on the highest points. Then the system measures the distance between the line and 3D surface data. Unlike its physical counterpart and in addition to detecting the location and type of defect (such as a dent or bulge), the digital whetstone also provides information about the lateral extent of the defect, as well as the height and depth, which are important indications of how critical a defect is. The result is displayed in colors as a defect map. During inline checks directly behind the injection moulding machine, the system makes an automated OK/NOK decision based on predefined threshold values.